STT-shaft twist tester NV

Twist test with a video camera

Twist test on the monitor with industrial camera solutions

Twist structures can be highly location-dependent over the circumference of the sealing seat. This location dependency is characterized by varying microstructure components of roughness and waviness. The periodicity of the swirl structure is disturbed, but parts of the sealing seat surface cause leaks due to increased swirl structures. In such cases, a 100% inspection of the sealing seat surface over the circumference is advisable.

Application background

Measurement method

Twist structures can be highly location-dependent over the circumference of the sealing seat. This location dependency is characterized by varying microstructure proportions of roughness and waviness. The periodicity of the swirl structure is disturbed, but parts of the sealing seat surface cause leaks due to increased swirl structures. In such cases, a 100% inspection of the sealing seat surface over the circumference is advisable.

Twist structures can be highly location-dependent over the circumference of the sealing seat. This location dependency is characterized by varying microstructure proportions of roughness and waviness. The periodicity of the swirl structure is disturbed, but parts of the sealing seat surface cause leaks due to increased swirl structures. In such cases, a 100% inspection of the sealing seat surface over the circumference is advisable.

By using the standardized Micro-Four-Thirds (MFT) bayonet catch, the test device can be equipped with commercially available digital cameras that have an MFT interchangeable lens adapter. The optical twist test is carried out in live image mode via the LCD display of the digital camera. The recorded test images can be transferred to a PC via a USB connection and integrated into a test report using the software supplied. Using application-specific sealing surface sample parts (tight, leaky, borderline), reference scattered light images can be identified and used as comparison samples for an optical quality test.

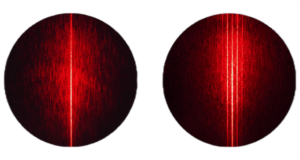

Particularly long-wave twist structures (DP> 200μm) are more difficult to detect due to this location dependency. The disturbed periodicity leads to interrupted diffraction lines in the optical twist test, which at period lengths of DP> 200 µm also have very small distances from one another and are therefore difficult to resolve for the eye. The optical image of the scattered light images enlarged by a factor of 4 with the help of a video camera and that on the screen leads to a significantly improved resolution of long-wave twist structures (200 – 500 μm). With the help of shaft lead tester STT R100 NV, 100% checks of the sealing seat surfaces can preferably be carried out.

Intended for stationary, production-related testing operations, the twist testing device is equipped with a video camera and connected to a monitor. The video camera can also be read out with a PC using a standard television card. When rotating the shaft between tips or in a lathe chuck, the disturbed diffraction lines on the screen can be compressed into standing lines that indicate the presence of a twist structure when the STT R100 NV is attached.

Specifications

Technical specifications

- Optical twist tester with a video camera for live image transmission on a monitor

- 4 times enlarged image of the spread pattern for the resolution of long-wave twist structures (DP> 200μm)

- PAL composite video signal (optionally also with USB connection)

- Twist period measuring range: DP 20 – 200 μm

- Twist depth: Dt> = 200 nm *

- Axial back focus: 15 mm

- Shaft diameter: 5 – 200 mm

- Illumination source: laser diode module laser class 2

* Specification for Rz = 2 μm (specification depends on roughness and twist period, permissible roughness. Ra 0.1 – 0.5 μm)

Optional accessories

Some technical accessories

Battery charger for STT

Charger + 2x battery (similar to picture)

Voltage (batteries): 3.6 volts (branded lithium-ion batteries)

high quality universal 2-channel charger

LED status display

This article is suitable for the following models: STT NO, STT NK, STT NV